Aluminum Stamper

This wax seal stamper was a gift for my brother for his wedding. I modeled the ideal shape in Rhino and split it in half to make an ideal CNC milling file. I also made another file for the box interior to be milled as a case and these two geometries were milled at the same time.

Once the milling process was over I took both halves of the stamper shape and glued them together with spray adhesive. I glued a riser to the bottom of the stamper with more spray adhesive. I then buried the foam into the sand leaving only the riser exposed. I then put a steel can around the riser to act as a funnel.

I had previously melted down several aluminum cans in my home made foundry and removed all the slag. I cast them into a muffin pan to make pure slugs. I re-melted these slugs at a later date and used the process of lost foam casting to make the solid aluminum stamper. I poured the molten metal on top of the riser and let the foam melt away. About 20 minutes later I pulled the stamper out of the sand and cinched it in the water.

To clean up the shape I cut off the extra aluminum that was the riser and spent some time on the belt sander making the shape smooth. I then polished the stamper with aluminum polish.

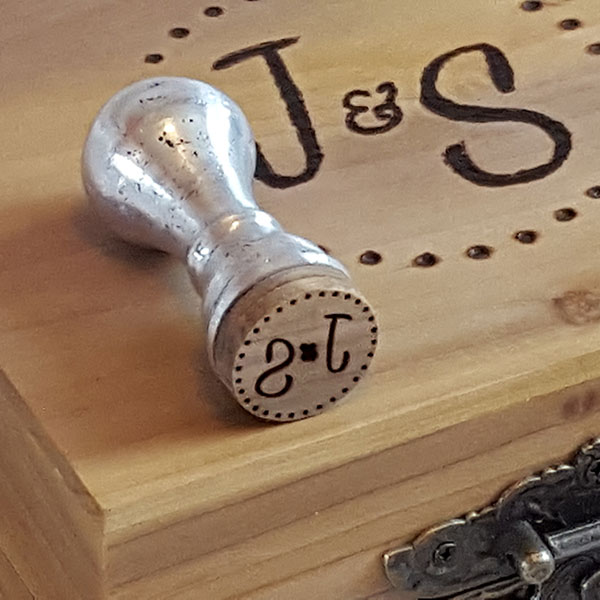

To make the logo for the stamper I planed down some poplar to 1/8” and ran a laser cut file. It had two layers to it; the basic cut out geometry and then the etch of the logo on the back piece. I finished the wood with boiled linseed oil and glued it to the aluminum stamper.

The box is made of poplar and is put together with simple miter joints at the corners and rabbet joints along the top and bottom piece. To make the box a little more ornate I printed out their logo on transfer paper and transferred the ink to the top of their box and then burned it in with my pyrography tool. I finished the box with boiled linseed oil and then pasting wax. I attached the clasp and hinges and then put the milled holder and aluminum stamper inside.